1, the use of single-chip software operation 2, the use of imported closed-type non-fluorine compressor 3, the sound cover, cleaning tank are made of high-quality stainless steel 4, the equipment is good sealing, with sound insulation, heat in

1, the specific level of protection alarm function 2, the instrument operation program using SCM software or Liquid Crystal Touch Screen PLC program control 3, display product function parameters 4, display memory and set the ultrasonic workin

1,304 stainless steel liner, high temperature corrosion resistance. 2, one-click Operation, easy to use. 3. High frequency cleaning, 40,000 high frequency oscillations per second. 4,360 ° no dead angle, automatic cleaning. 5, waterproof de

1, 304 stainless steel tank, high temperature corrosion resistance. 2, one-click Operation U, easy to use more easily. 3, High frequency cleaning, 40,000 high frequency oscillations per second. 4, 360 ° no dead angle, automatic cleaning. 5,

1. 42000 times per minute, high frequency vibration, world besmirch, only fast not broken. 2.Multiple cleaning modes, optional. 3. 360 ° no dead angle, efficient decontamination. 4. Clean your home with a variety of items. 5. Soak and clea

1, with the working process parameters of the printing function and tracing. 2. Automatic feed and drain function. 3. Automatic Water Inlet and outlet. 4. Automatic chemical additives (optional). 5. ADD enzymes and consumables automaticall

1. The display screen adopts LED visualization LCD digital display, which is clear and clear at a glance. 2. Automatic frequency sweep function, the data error of the analysis object is greatly reduced, the efficiency of cleaning objects is improved, a

1, the use of city-state motors, accurate positioning, flexible arm handling; 2, fully closed management, to ensure that the cleaning environment clean; 3, Mitsubishi Programmable PLC automatic control, Taiwan Weilun man-machine interface; 4,

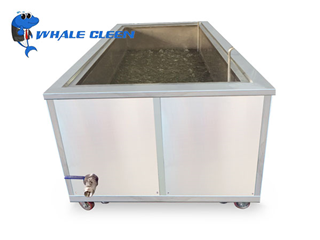

1, The whole machine is made of SUS304/316 stainless steel, heat resistant and corrosion resistant. 2, Use thickened tank with good heat resistance and corrosion resistance, seamless, leak-proof. 3, Iindustrial-grade transducer, clean strength is stro

1, Use PLC control and touch screen operation. Select imported components assembled into the manipulator. It has high positioning accuracy, smooth action, reliable operation, compact structure. 2, The manipulator of the gantry arm can be controlled aut

1. Ultrasonic transducer has high vibration speed and is fixed directly on the bottom of the cleaning tank through bolts. So that the strength is greatly improved. Compared with a magnetostrictive vibrator, the energy efficiency is increased by more than

1, Bubble cleaning is without any dead angle. It can make cleaning liquid and dirt contact more thoroughly. So that the water molecules in the agitation and the joint action of ultrasonic high-speed movement of the surface stains have a lasting impact. So